Process Simulate can be used to create event-driven simulations over incorporating a range of aspects, including:

From single robot simulation in the ’80s, to car body cell simulation in the ’90s with Robcad, Process Simulate allows users to simulate multiple production lines operating simultaneously within a single study. With robots or cells functioning simultaneously, there’s no need to make assumptions for any events happening in the factory, all possible interactions between cells and their knock on effects are accounted for. When all events are simulated at the same time, this gives greater accuracy when compared to working with a single robot or cell at a time.

Many clients have had sucess migrating existing Robcad cells and projects directly into Process Simulate. This means manufacturers can take advantage of using the intuitive Process Simulate userface, as well as benefitting from software updates along with hardware and operating system support to keep the program running efficiently.

You can read about how Kuka Brazil upgraded from Robcad to Process Simulate with Siemens Digital Industries Software here.

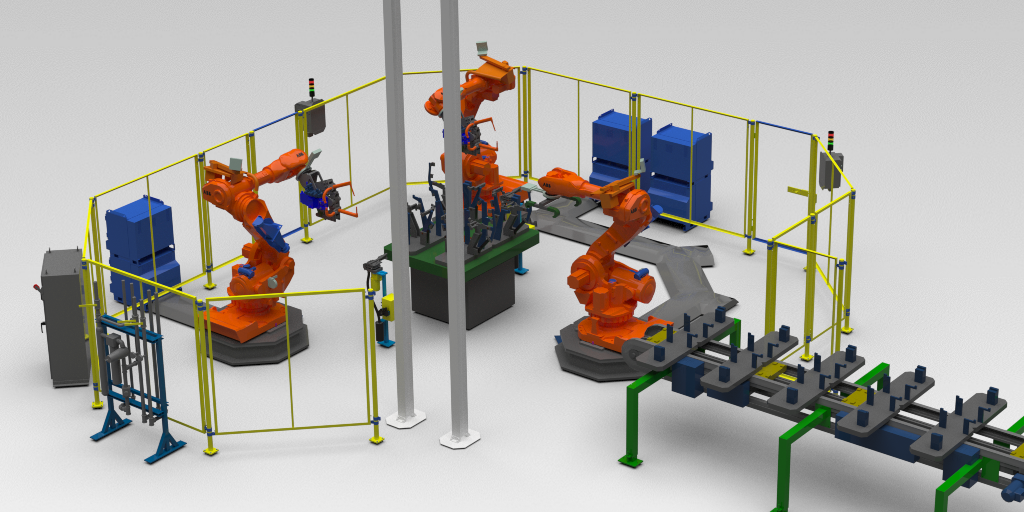

Virtual commissioning is the simulation and debug of PLC code using a ‘digital twin’ – this is an exact functional replica of the production line in the virtual world, where unlimited testing can take place in an environment with no risk. The virtual commissioning approach facilitates interdisciplinary collaboration between mechanical and electrical teams much earlier on in a project, allowing more of the programming to be completed and tested before physical installation. This leads to less time spent on the factory floor, as seen in the KUKA Brazil case study from Siemens Digital Industries.

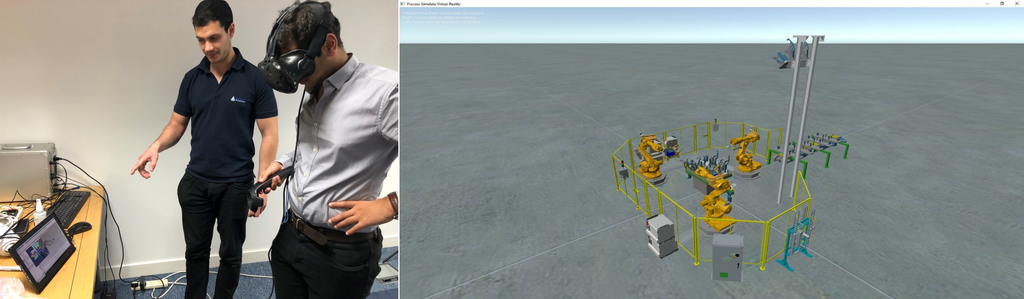

Process Simulate seamlessly integrates with HTC Vive or HTC Vive Pro virtual reality headsets, handheld controllers and on screen views so designs can be easily shared with a wider audience. Exploring lines in virtual reality helps to effectively convey information and review designs with a range of technical and non-technical stakeholders. Additionally, Virtual Reality naturally lends itself to the evaluation of human factors in a production environment such as operator lines of sight and proximity to cobot movement.